The cement silo typically has two sorts which include the bolted cement silo and the complete welded cement silo. But the capabilities is the equal. If you want to improve the performance as opposed to labor paintings, we choose the cement silo together with the screw conveyor. for some foreign customers we layout the bolted cement silo. This form of silo is in separated which can easily loading into the bins.

Contact Now

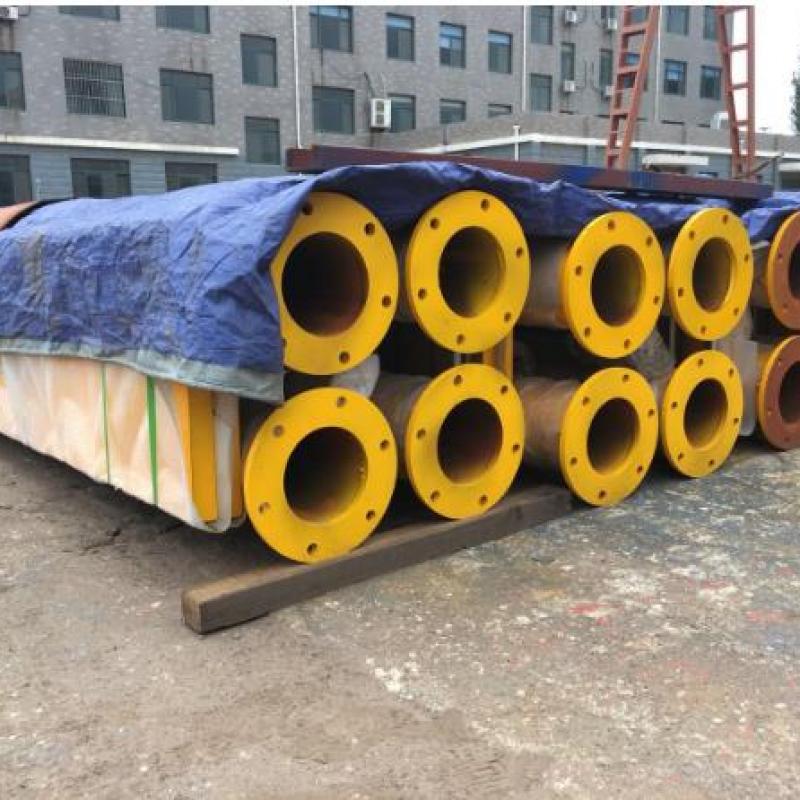

Usually the screw conveyor can effectively transport the cement and other powder material to the weighing hopper form the silo. With the screw conveyor it can avoid the pollution and improve efficiency.The screw conveyor is divided according to the diameter, like the 168mm, 219mm. The small size of the concrete mixing station will choose the 168 and 219mm.

Contact Now

Commonly the screw conveyor can correctly shipping the cement and other powder material to the weighing hopper form the silo. with the screw conveyor it may avoid the pollution and improve performance.The screw conveyor is split in line with the diameter, just like the 168mm, 219mm. the small size of the concrete blending station will choose the 168 and 219mm.

Contact Now

Usually the screw conveyor can successfully delivery the cement and unique powder cloth to the weighing hopper form the silo. with the screw conveyor it may avoid the pollutants and enhance overall performance.The screw conveyor is split regular with the diameter, much like the 168mm, 219mm. the small duration of the concrete blending station will pick the 168 and 219mm.

Contact Now

Normally the screw conveyor can correctly delivery the cement and specific powder to the weighing hopper form the silo. With the screw conveyor it is able to keep away from the pollutants and enhance commonplace common typical performance.The screw conveyor is split everyday with the diameter, much like the 168mm, 219mm. the small length of the concrete mixing station will pick out out the 168 and 219mm.

Contact Now

Commonly the screw conveyor can effectively delivery the cement and particular powder cloth to the weighing hopper shape the silo. with the screw conveyor it is able to keep away from the pollutants and beautify commonplace average overall performance.The screw conveyor is split everyday with the diameter, much like the 168mm, 219mm. the small duration of the concrete mixing station will choose the 168 and 219mm.

Contact Now

Commonly the screw conveyor can correctly shipping the cement and precise powder fabric to the weighing hopper shape the silo. with the screw conveyor it is able to keep away from the pollution and decorate common overall performance.The screw conveyor is break up ordinary with the diameter, just like the 168mm, 219mm. the small length of the concrete mixing station will select the 168 and 219mm.

Contact Now

Commonly the screw conveyor can effectively delivery the cement and unique powder cloth to the weighing hopper shape the silo. with the screw conveyor it may avoid the pollution and decorate not unusual average overall performance.The screw conveyor is cut up everyday with the diameter, just like the 168mm, 219mm. the small period of the concrete blending station will pick out the 168 and 219mm.

Contact Now

Commonly the screw conveyor can effectively shipping the cement and different powder cloth to the weighing hopper shape the silo. with the screw conveyor it may avoid the pollutants and improve overall performance.The screw conveyor is split consistent with the diameter, just like the 168mm, 219mm. the small length of the concrete mixing station will pick the 168 and 219mm.

Contact Now

The cement silo commonly has kinds which consist of the bolted cement silo and the entire welded cement silo. However the capabilities is the identical. as a way to enhance the performance instead of exertions paintings, we select the cement silo collectively with the screw conveyor. For some overseas clients we design the bolted cement silo. this kind of silo is in separated that could easily loading into the packing containers.

Contact Now

What's the cement silo? why we use this sort of device to storage the cement and a few power substances? Cement silo is one kind of tank which use to storage the powder substances. this type of material need to keep away from the liquid substances, so we need the tank sealed closely. what’s greater some big concrete blending plant cannot be paused due to the concrete have to continuously deliver. some small tank can't guide so we use the cement silos. Cement silo collectively with screw conveyors can supply the cement without worry approximately the supplement.

Contact Now

JS1500 Concrete Mixing PlantBatching system A wide range of aggregates can be weighed at the same time with high efficiency. The belt conveyor is equipped with a spiral tensioning device at the end of the belt conveyor, which can adjust the belt tension at any time to prevent the belt from slipping and running off, ensuring efficient operation. The head of the belt conveyor is equipped with a material stopping device, which effectively prevents spilling of material. The aggregate hopper and the side wall of the aggregate weigher are equipped with vibrators, which facili

Contact Now

The twin-shaft mixer named because it has two horizontal mixing shafts. It can mix wet concrete, dry hard concrete, plastic concrete, light aggregate concrete and various mortars.

Contact Now

1.Multifunctional mixer. Double horizontal shaft mixer produces convection and extrusion effect on materials, suitable for mixing all kinds of dry and hard concrete, with strong production capacity, good quality and high utilization rate with less input.2.

Contact Now

The concrete double horizontal shaft forced mixer is specifically used for mixing diverse powder materials. this is, it could produce all styles of powdered mixing materials. its combination can be moist fly ash, calcium carbide dust, phosphogypsum, sand and gravel, furnace slag, and so on. it's miles especially used as the assisting host of numerous wellknown brick, grey sand brick and other manufacturing strains.

Contact Now

The concrete double horizontal shaft forced mixer is mainly used for mixing various powder materials. That is, it can produce all kinds of powdered mixing materials. Its aggregate can be wet fly ash, calcium carbide mud, phosphogypsum, sand and gravel, furnace slag, etc. It is mainly used as the supporting host of various standard brick, gray sand brick and other production lines.

Contact Now

The concrete double horizontal shaft compelled mixer is mainly used for blending numerous powder substances. this is, it may produce all sorts of powdered blending materials. its combination may be wet fly ash, calcium carbide mud, phosphogypsum, sand and gravel, furnace slag, and so forth. it's far in particular used as the helping host of numerous widespread brick, gray sand brick and different manufacturing strains.

Contact Now

Backpack kind, additionally known as handy kind, the battery will be positioned in the battery backpack, connected to the battery energy may be used, no energy restrictions, can also be used with a energy converter plugged in.

Contact Now

1250L planetary mixerThe 1250L planetary mixer's feeding extent is 1875l approximately 3000 kg. The overall weight is 6000kg, it's far extensively used in special field now not simplest the concrete blending. As we are recognise there are more and more concrete merchandise no longer most effective the moist concrete but additionally some dry and semi-dry.

Contact Now

Planetary mixer has a completely unique and novel shape of blending, the kettle has or 3 multi-layer slurry blade stirrer and 1 to two automatic scrapers, the stirrer within the axis of the kettle body whilst rotating round its personal axis at exceptional speeds, excessive-pace rotation, in order that the material within the kettle body for complex motion, problem to strong shear and rub collectively its performance is typically several times the everyday mixer. Planetary mixer features: the host adopts planetary equipment reducer layout, low noise, high mechanical efficien

Contact Now

High efficiency, its mixing principle determines its stronger mixing efficiency than ordinary mixers. Wide range of use, research shows that the planetary mixer can be applied to most materials with viscosity of 1 million pcs and solid content of 90% or less.

Contact Now

The drive of the planetary mixer with vertical shaft is pushed by way of a specially designed hardened gear reducer. a bendy coupling or a hydraulic coupling (non-obligatory) is installed between the motor and the reducer to make certain ordinary starting even at complete load.

Contact Now

The drive of the planetary mixer with vertical shaft is driven by a specially designed hardened gear reducer. A flexible coupling or a hydraulic coupling (optional) is installed between the motor and the reducer to ensure normal starting even at full load. The power generated by the reducer makes the stirring arm do both self rotation movement and rotation movement, and the scraper arm does the rotation movement.

Contact Now

PL800 Aggregate Batching MachineryPL800 Aggregate Batching Machinery adopts 2.5 cubic meters hopper which can match with two to four hoppers. The measuring accuracy is about 2%, and we use two weighing types include belt weighing and single hopper weighing. This two kinds weighing type both can provide accurate aggregate to the concrete mixer.And this kind of batching machinery is popular in foreign market especially is Africa market. And we can use the independent control for the batching machinery and the concrete mixer which can save customers cost.

Contact Now