Stationary Asphalt Mixing Plant

Application:Stationary batch type asphalt mixing plant is mainly used in the road construction of freeway, highway, expressways, national road, main road, city road, airport, ports, water conservancy and bridge.

Capacity:40t/h to 320t/h

Motor Power:150kw to 800kw

ZAP-S series Stationary Batch Asphalt Mixing Plant are available from 40TPH to 320TPH, and is most popular for its high output and high performance.

Main advantages:

• Cost effective solutions for your project.

• Multi-fuel burner for choose.

• Environmental protection, energy saving, safe and easy to operate.

• Low maintenance operation & Low energy consumption & Low emission.

• Optional environmental design - sheeting and clad to customers requirements.

• Rational layout, simple foundation, easy to be installed and maintenance.

Cold Aggregate Feeding System

- The belt feeder adopts frequency conversion speed regulation, wide speed regulation range and high work efficiency.

- Each discharge port has a material shortage alarm device, and if there is no material or arching, it will alarm automatically .

- There is a vibrator on the sand bin to ensure normal operation.

- A screen is placed on the top of the cold aggregate hopper to avoid large material input.

- The conveyor belt adopts a jointless round belt, which runs smoothly and has a long service life.

- There is a simple screen to avoid large material input in the input port of the feeding belt conveyor, ,which can improve thermal efficiency, and ensure the working reliability of the drying drum, hot aggregate elevator and vibrating screen.

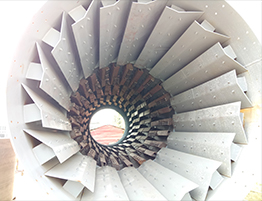

Drying System

Drying System

- Optimizing the blade geometry of the dryer makes the drying and heating process extremely efficient, reduces energy consumption, and increases the heating efficiency by 30% compared with the conventional design; due to the high heating efficiency, the surface temperature of the drum is relatively low, so the cooling period after operation is greatly shortened.

- Completely insulated and composite aggregate drying drum. The support roller is driven by the friction of the motor and the gear unit.

- Adopting the famous brand Honeywell temperature intelligent control system.

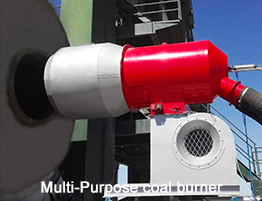

Combustion system

- Using Italian brand high combustion efficiency burners to ensure low exhaust emissions (such as carbon dioxide, low NO1 & NO2, sulfur dioxide).

- Diesel, heavy oil, natural gas, coal or multi-fuel burners.

- Using international standard parts, the maintenance cost is low.

Vibrating screen

- Improve vibration and amplitude to optimize the impact on the available screen.

- A wear-resistant charging system with a uniform distribution of the particle mixture.

- Wide open door for easy access, simple screen replacement and reduced downtime.

- The best combination of vibration direction and screen box inclination ensures ratio and screening efficiency.

Weighing system

- Use the well-known brand TOLEDO weigh sensor to ensure accurate weighing and ensure the quality of asphalt mixture.

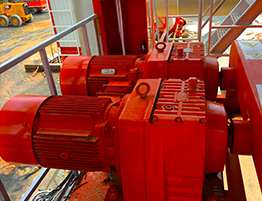

Mixing system

- The mixer is a three-dimensional hybrid design with an array of long arms, short shaft diameters and bidirectional mixing blades.

- The discharge process has been completely redesigned with minimal discharge time.

- The distance between the blade and the bottom of the mixer is also limited to the optimum minimum.

- Bitumen is sprayed from multi-points evenly over aggregate by one pressurized bitumen pump to achieve full coverage and high mixing efficiency.

Dust Collecting System

- Gravity type primary dust collector collects finer dust and saves consumption.

- The discharge of the secondary dust collector in the baghouse is less than 20mg/Nm3, which is environmentally friendly.

- Using the US Dopont NOMEX filter bags, it is resistant to high temperature and has a long service life. The filter bag can be replaced easily and without special tools.

- Intelligent temperature control system, when the dust temperature is higher than the set value, the cold air valve turns on the cooling automatically to avoid the filter bag being damaged by high temperature.

- Using high-pressure pulse cleaning technology, it is beneficial to reduce bag wear, prolong service life and improve dust removal performance.

Bitumen supply system

- The bitumen tank is sturdy and durable. Bitumen tanks of different sizes and capacities are available upon request. Bitumen tanks are covered with rock wool insulation and galvanized sheets to minimize heat loss.

- The bitumen tanks is heated by a heat conduction oil to ensure the temperature of the bitumen.

Control system

- Using Germany SIEMENS electrical components, it can work stably even under harsh working conditions.

- Using Japan's OMRON PLC and touch screen, which has strong data processing capability, automatic data sheet control, and can store various operational data in real time.

- All system power switches can be controlled through the control panel, which is easy to operate and easy to control.

- Multi-language compatibility, the display language can be selected according to customer preferences.

- The control cabinet is IP55 rated to meet the highest industry standards in the world.

- Container control room with thermal and acoustic insulation.

- Global remote automatic detection function.

Related News

Submitted successfully

We will contact you as soon as possible