Advanced HLS120 Belt Type Concrete Batching Plant

Model: HLS120 Concrete Mixing Station Type: Inclined belt

Productivity: 120 cbm/hour Weight: 60,000kg

Matched Mixer: JS2000 Power of the Mixer: 2*37KW

Input Capacity: 3000L Output Capacity:2000L

Batching Machinery: 4*20cbm Belt Transport Ability: 700T/H

Discharge Height: 4.2m Total Power: 145KW

Advanced HLS120 Belt Type Concrete Batching Plant

1.Modular layout, convenient to collect and disassemble;

2.Adopting high-efficiency mixer,excessive production performance, appropriate for diverse concrete mixing wishes

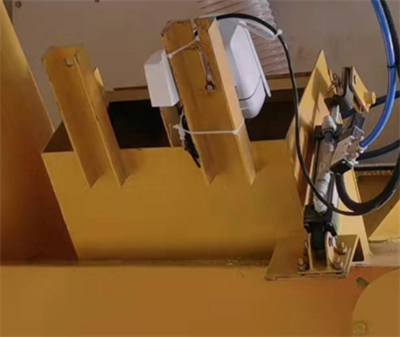

3.The aggregate size device achieves excessive-precision size of mixture by using optimizing the release door shape, improving the vibration shape of the vibrator, and increasing the closing speed of the discharge door.

4. There may be a liquid garage bag at the top of the water/additive weighing scale so that it realizes the coarse-pleasant dimension.

5. With siemens industrial control laptop because the platform, the manufacturing control software adopts the maximum advanced automatic scale compensation and deduction scale era in china to make sure that the dimension accuracy of various uncooked materials meets the technical necessities of high-speed railway production;

Model | HLS60 | HLS90 | HLS120 | HLS180 | HLS240 | ||

Rated Productivity(m³/h) | 60 | 90 | 120 | 180 | 240 | ||

Mixer | Mode | JS1000 | JS1500 | JS2000 | JS3000 | JS4000 | |

Driving Power (KW) | 2*18.5 | 2*30 | 2*37 | 2*55 | 2*65 | ||

Discharge Capacity (L) | 1000 | 1500 | 2000 | 3000 | 4000 | ||

Max Aggregate Size (MM) | ≤60/80 | ≤60/80 | ≤60/80 | ≤60/80 | ≤60/80 | ||

Batching Machinery Size (m³) | 15 | 15 | 20 | 25 | 40(underground) | ||

Measuring Accuracy | Aggregate | 2% | 2% | 2% | 2% | 2% | |

Cement | 1% | 1% | 1% | 1% | 1% | ||

Water | 1% | 1% | 1% | 1% | 1% | ||

Additive | 1% | 1% | 1% | 1% | 1% | ||

Maximum Weighing (kg) | Cement | 800 | 1000 | 1000 | 1800 | 2400 | |

Water | 400 | 400 | 500 | 800 | 1000 | ||

Additive | 25 | 25 | 40 | 70 | 100 | ||

Discharge Height (M) | 4.2 | 4.2 | 4.2 | 4.2 | 4.2 | ||

Total Power(kw) | 90 | 125 | 160 | 200 | 270 | ||

Detailed Information:

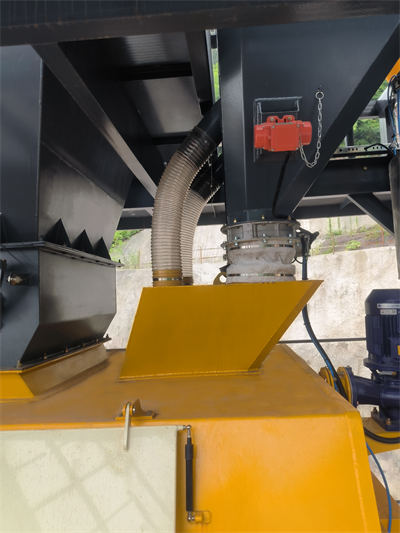

First: The main station dust collecting

1. Adopt pulse dust collector to actively collect the dust generated by the equipment

2. Dust collector is placed on the top of the middle storage bin, dust removal efficiency reaches 99.9%.

3. Automatic pulse cleaning of the dust collected by the filter bag to avoid secondary dust pollution

4. Open structure, easy to repair and maintain

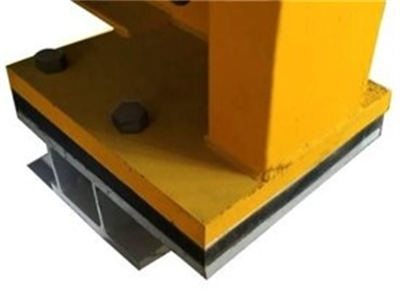

Second. Low noise

1. Mixer legs are equipped with shock absorbing pads to reduce the vibration generated by the operation of the mixer and reduce the noise of the equipment

2. The sound insulation effect of high quality rock wool board is more than 50% higher than the traditional one.

3. The use of screw air compressor, low noise, large air volume, low failure rate

4. Ground bin batching machine, significantly reduce the noise generated by aggregate measurement

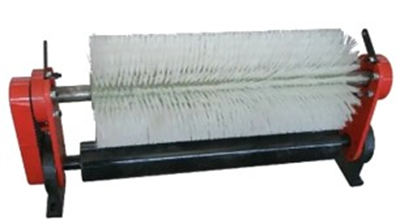

Third. Famous brand accessories

Fourth:

The main machine is equipped with a camera to monitor the internal situation of the main machine in real time; it can be equipped with a high-pressure cleaning device to reduce the difficulties of workers cleaning the mixer and the downtime caused by holding the shaft.

FAQ

1. What’s the difference of the HZS and HLS Concrete Mixing Station?

HZS series means the aggregate lifting type is the skip hoist and the HLS series is the inclined belt.

2. How we choose the size of the concrete mixing station?

Usually we suggest customer choose the size and type according to the coverage area and the productivity of per hour. For example, customer has big space with 200 cubic meters concrete each day, then we can suggest the HLS240 concrete mixing station.

3. What’s the advantages of the bolted cement silo?

Bolted cement silo is not only designed for foreign customer but also for our domestic market.

For foreign customer it can save delivery space which will reduce the freight charges and for domestic market it can protect the environment because it avoid the outdoor welding.

4. What customer should provide before we design?

Commonly, we need the know how many kinds of the aggregate, the powder, additive type. This is the most important. What’s more the language and voltage is necessary.

5. The installation

About the installation we will arrange engineer to guide and train the operate workers, so no worry about this.

6. Payment terms and production cycle

30% prepayment when place the order, the balance should pay before delivery. Usually the delivery time is 20 days after the prepayment.

Related News

Submitted successfully

We will contact you as soon as possible