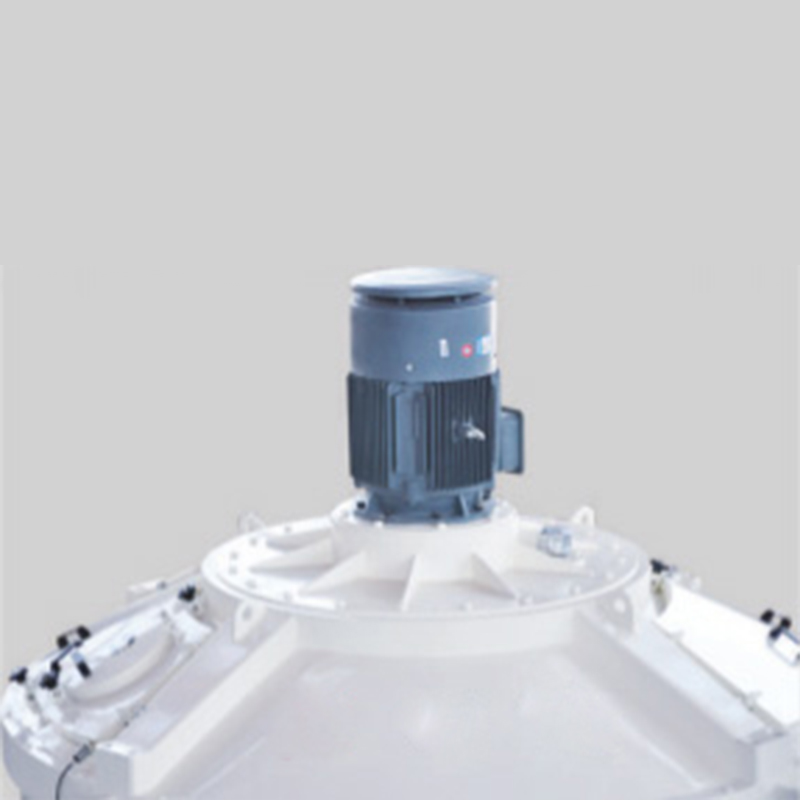

Hopper Small Planetary 500L Concrete Mixer

1.Planetary mixer is suitable for mixing all high quality concrete (dry hard, semi-dry hard and plastic concrete) and achieving high homogeneity in the shortest possible time, it is also suitable for glass, ceramics, refractory materials and other industries.

2.The specially developed gearbox can distribute the power balance to each mixing device effectively, which can ensure low noise transportation of mixing colleges and universities even under harsh production conditions. At the same time more space-saving, compared with the traditional gearbox, the maintenance space of the mixer can be improved by 30%.

3.Flexible coupling and hydraulic coupling (optional item) can effectively protect the transmission system from the impact of overload.

The 500L planetary mixer's feeding extent is 500l approximately 1200 kg. The full weight is3100kg, it is widely used in exceptional field now not simplest the concrete blending.

As we are understand there are an increasing number of concrete products no longer simplest the wet concrete however also some dry and semi-dry. This sort of mixer can mix greater deeply than the horizontal mixer but the charge is higher.

Item | 500L | 750L | 1000L | 1250L | 1500L | 2000L |

Feeding Volume | 750L | 1125L | 1500L | 1875L | 2250L | 3000L |

Feeding Volume | 1200 kg | 1800 kg | 2400 kg | 3000 kg | 3600 kg | 4800 kg |

Output Volume | 500L | 750L | 1000L | 1250L | 1500L | 2000L |

Mixing Power | 30/37 | 37/45 | 45/55 | 45 | 55/75 | 75/90 |

Mixing star*Mixing Blade | 1*2 | 1*3 | 2*2 | 2*2 | 2*2 | 3*2 |

Side Scraper/Discharge Scraper | 1/1 | 1/1 | 1/1 | 1/1 | 1/1 | 1/2 |

Discharge power | 2.2kw | 2.2 kw | 2.2 kw | 2.2 kw | 2.2 kw | 3 kw |

Weight | 2500 kg | 3500 kg | 5500 kg | 6000 kg | 6500 kg | 8500kg |

How to choose the mixer type?

MPC vertical shaft planetary mixer and JS double horizontal shaft forced mixer have in common that they can be used as the main machine of concrete mixing plant.

The difference lies in the design and working principle of the mixing system

1.The mixing system of the double horizontal shaft mixer is composed of two horizontal mixing shafts which drive the mixing arms and blades to mix the materials forcibly through rotation.

2.The structure of the mixing system of vertical shaft mixer is standing up, and the mixing arms and mixing blades are distributed in all directions at a reasonable angle. In operation, with the rotation of the main shaft, each mixing blade does planetary movement. When running, the spindle rotates and drives the blades to squeeze and turn the material in a compound action such as compulsory mixing. The mixing process has no dead angle, which is suitable for mixing materials with small particle size and high requirements for uniformity.

In terms of function and application, vertical shaft mixer can mix more kinds of materials, suitable for mixing all kinds of dry and hard materials, and can be used in refractory materials, pipe piles, prefabricated components, ceramic granules, brick making and other fields. And the double horizontal shaft mixer is usually only used for concrete mixing production.

Related News

Submitted successfully

We will contact you as soon as possible