Concrete Mixing Plant 200t Cement Silos

Model: SNC200 Discharge Height: 6500m

Diameter: 4400mm Volume: 147m³

Capacity: 200 Ton Container: One set (40HC)

Concrete Mixing Plant 200t Cement Silos

The snc200 ton bolted cement silo’s discharge height is 6500mm with 4400mm diameter. one-of-a-kind from the snc50-one hundred fifty bolted cement silo, the diameter is greater that allows you to reduce the whole top. for some places close to the ocean the wind is very heavy so we need to hold the safety.

In home market we choose to use the entire set silo that's welded in the patron's website online.

But for export equipment we need to store the freight costs and without difficulty for shipping, this type of bolted cement silo is consumer's first desire.

Concrete Mixing Plant 200t Cement Silos

NO. | Model | Discharge height | Diameter of body | Parts of body | Material size | m3 | (t) |

1 | SNC50 | 4200 mm | 3100mm |

4*3 | upper coneδ3,body partδ3,lower coneδ4 ,legs φ219*4 | 38 | 3.4 |

2 | SNC100 | 4200 mm | 3100mm |

4*6 | upper coneδ4,upper and lower partδ4,body partsδ3,lower coneδ5+δ4,legs φ219*5 | 70 | 5 |

3 | SNC150 | 4200 mm | 3100mm |

4*9 | upper coneδ3,upper of bodyδ4,body parts δ3,lower coneδ5,lower coneδ6+δ4, legs φ219*6 | 102 | 6.5 |

4 | SNC200 | 6500 mm | 4400mm | 6*6 | upper coneδ4,the top and bottom piece of bodyδ4.5,other body part δ4,lower coneδ6 +δ6+δ4,legsφ273*7 | 147 | 10.7 |

5 | SNC300 | 650 0mm | 5300mm | 8*6 | upper coneδ6,bodyδ6,lower coneδ8 +δ6+δ5,legs φ325*8

| 219 | 17 |

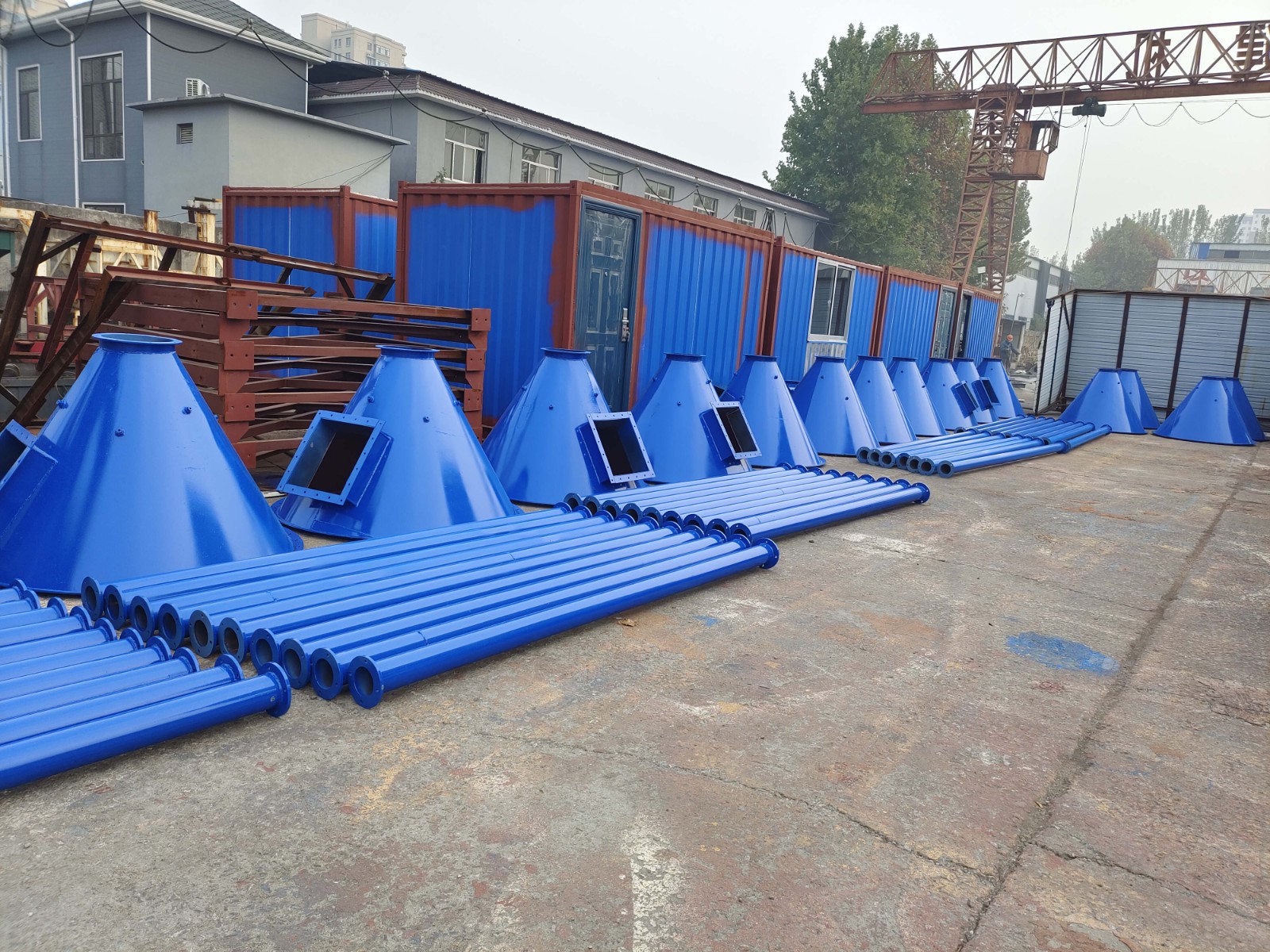

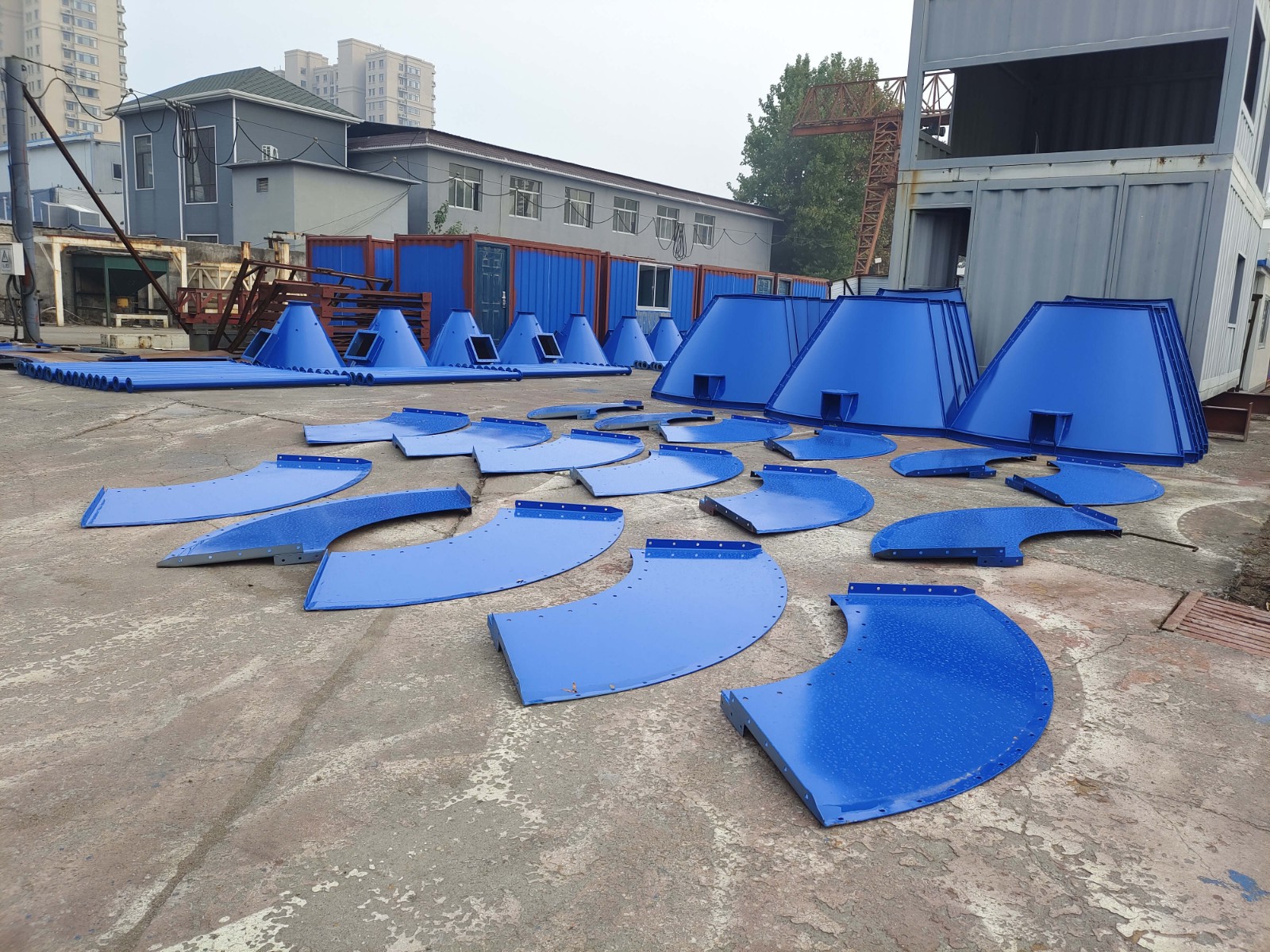

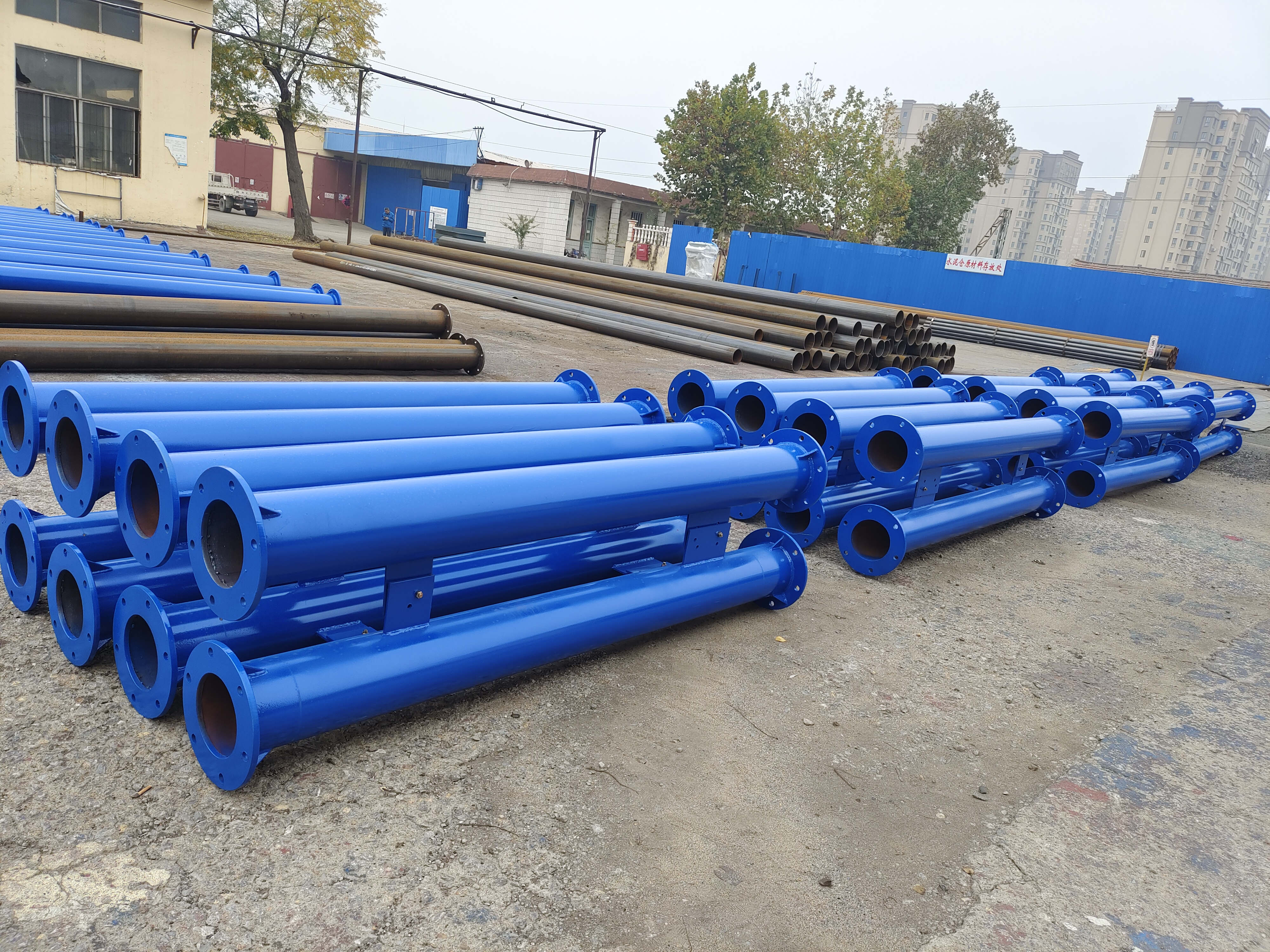

Main Parts of the Silos

Upper and Lower Cone

Support Legs

FAQ:

1. What’s the difference of the whole type and the bolted type cement silo?

The whole type silo is usually welded in the customer's site which can save the delivery charges and the limit of some road. The bolted type is for the foreign and some site not allow weld outside.

2. What’s the advantages of the bolted cement silo?

Bolted cement silo is not only designed for foreign customer but also for our domestic market.

For foreign customer it can save delivery space which will reduce the freight charges and for domestic market it can protect the environment because it avoid the outdoor welding.

3. What customer should provide before we design?

Commonly, we need the know the discharge height,the diameter, the total height and your country's voltage and frequency.

4. The installation

About the installation we will send you the installation videos, it is very easy and convenient for you to assemble.

5. Payment terms and production cycle

30% prepayment when place the order, the balance should pay before delivery. Usually the delivery time is 20 days after the prepayment.

Related News

Submitted successfully

We will contact you as soon as possible