HZSY60 Mobile Concrete Mixing Plant

At present, the mobile concrete mixing plant is mainly divided into two types: tractor type and trailer type, the chassis of the tractor type contains complete front and rear axles; the chassis of the trailer type has only the rear axle, and the front end is placed on the saddle bridge of the tractor.

1. Fast disassembly, easy to move

When transferring: except for screw conveyor and cement silo, the whole mobile concrete mixing plant can be towed and moved when the front end is dropped; others, such as walking platform, raised plate folded down, and all control cables do not need to be dismantled. All control cables do not need to be dismantled. The removed accessories can be taken away with the plant.

Xinjiant mobile concrete mixing plant is equipped with tyres, towing pins, travelling signal device, brake system, and the maximum speed allowed when trailer is towed is up to 50km/hour.

Installation: flat hardened ground is sufficient; dismantling requires the cooperation of a 30 tonne crane.

When storing: If the equipment is not used temporarily, keep the transport status when transferring to other places for transport with

2. Other performance and operation mode and principle are the same as fixed standard mixing plant (see HZS type concrete mixing plant).

3.All parts of the mobile mixing plant transport unit external dimensions are smaller than the container empty size requirements, the whole station transport requires three 40-foot containers.

1. Host chassis: the cantilevered mixing host chassis contains towing truck towing pins and parking legs; on the chassis, the mixer, cement and water admixture weighing scale is placed; the periphery is attached with inspection platforms and railings.

2. Control room: the control room is at the bottom of the chassis of the main machine, which is equipped with fully automatic control system of the mobile mixing plant, and the control system is the same as that of the stationary mixing plant; the control room serves as the front support point of the whole plant in working condition, and when it is transferred to the field for transport, the control room will be put away and collected in the inner hollow of the bracket; all the control lines do not need to be dismantled.

3. Aggregate batching and measuring: this system is located at the back end of the station, the upper part is aggregate (sand, stone) storage hopper, the storage hopper can be divided into 2 or 4 compartments, and set up heightening plate to increase the storage capacity, pneumatic operation in order to open the door, the aggregate measurement for a variety of materials cumulative measurement method. The bottom of the machine is equipped with a travelling rear axle and frame legs for working.

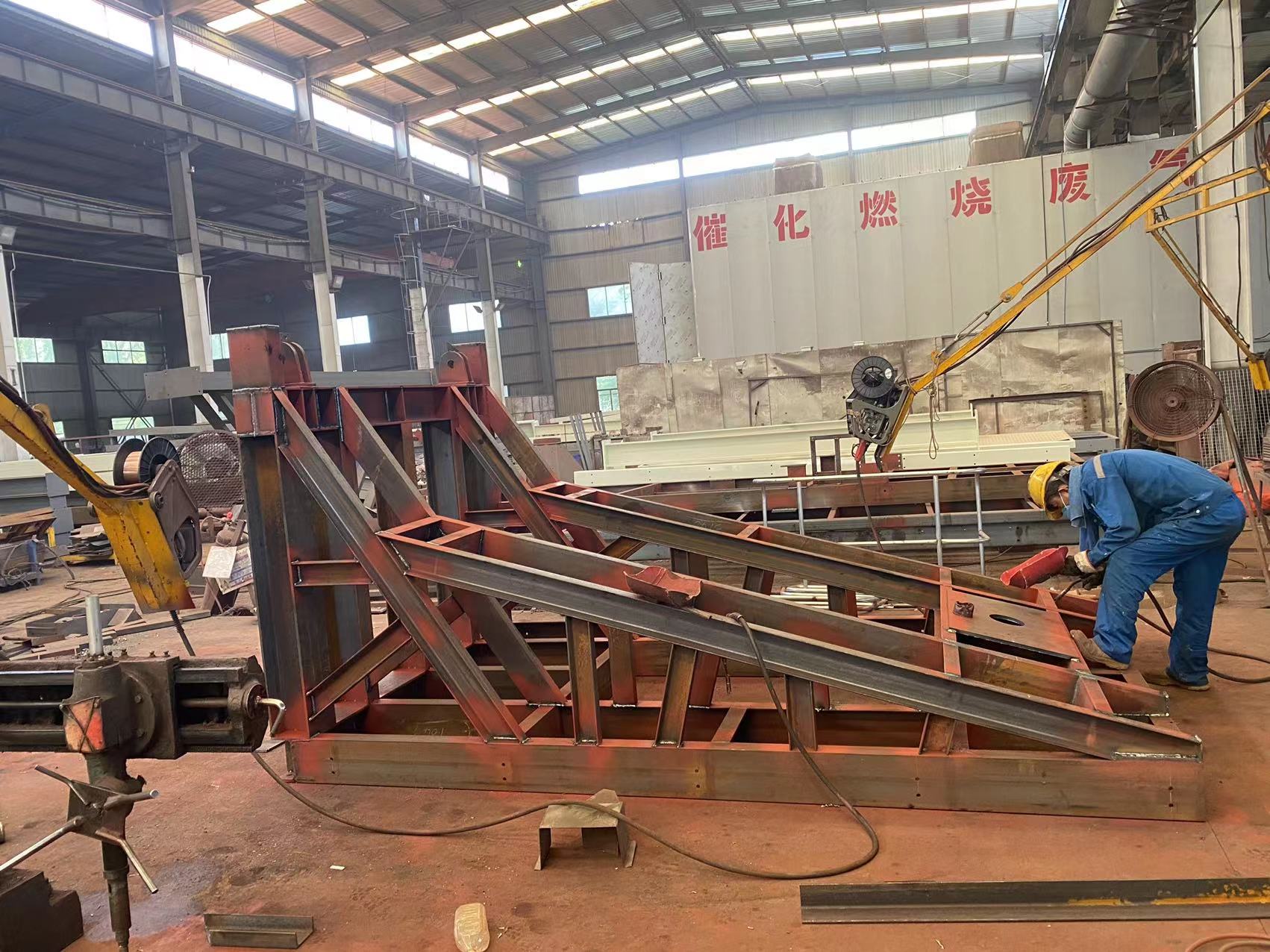

4. Belt conveyor frame: the frame is a truss structure connecting the host chassis and the aggregate batching frame, with a belt conveyor frame installed inside; the host frame, belt conveyor frame and batching frame are integrated to form the main structure of the whole mobile mixing plant.

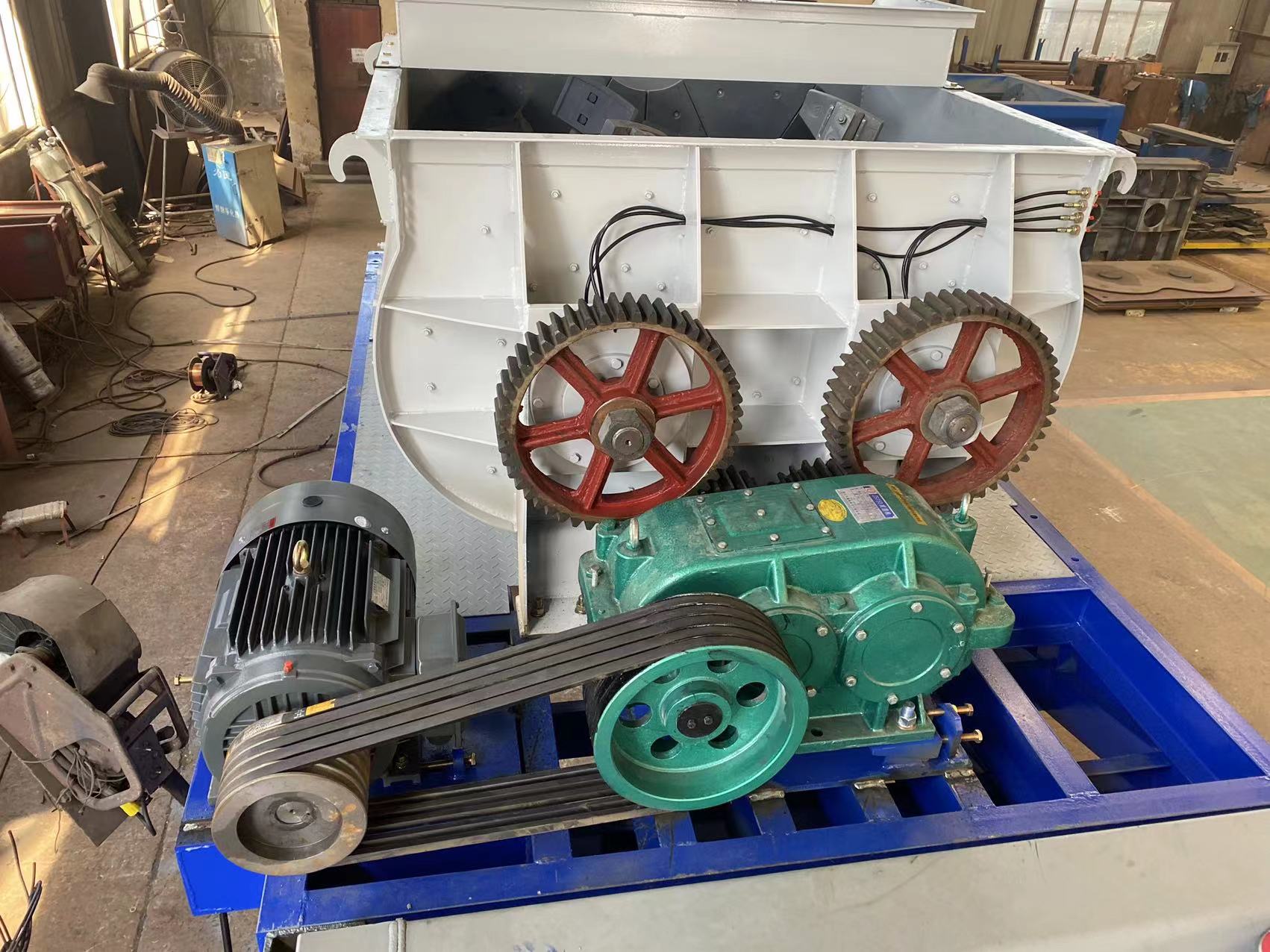

5. Mixing machine: JS-type forced mixer is generally used, which can quickly and evenly mix and complete the fluidity and dry hard concrete.

Factory workshop and office

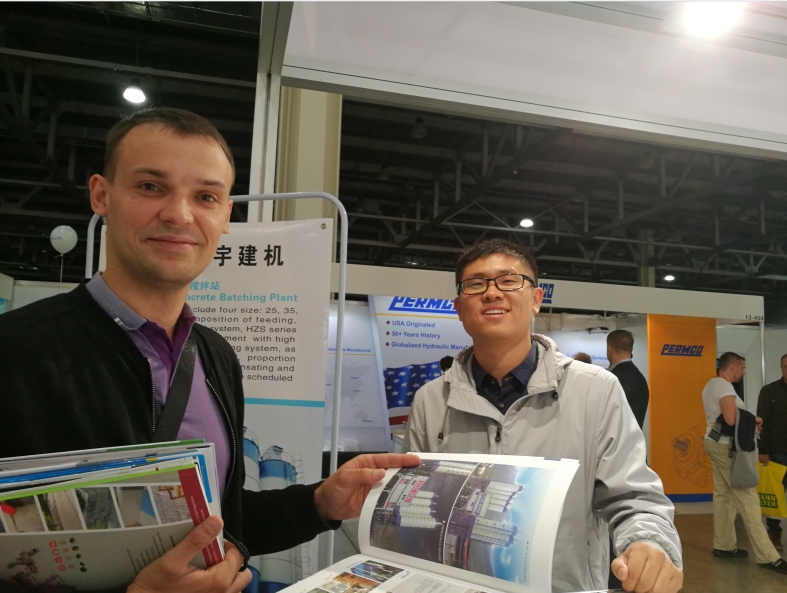

Our cases and exhibition